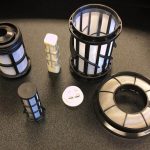

Custom Plastic Injection Filters

Gallery

Materials Used:

- Polypropylene (PP): Excellent chemical resistance, lightweight, cost-effective

- Nylon (PA6, PA66): High strength, abrasion resistance, and temperature tolerance

- Polyethylene (PE): Flexible, moisture-resistant, suitable for low-pressure applications

- Polycarbonate (PC): High clarity, impact resistance, heat resistance

- Acrylonitrile Butadiene Styrene (ABS): Tough, rigid, and ideal for complex shapes

- Polyether ether ketone (PEEK): Premium material for high-heat and aggressive chemical environments

- Polysulfone (PSU): Excellent hydrolytic stability for repeated sterilization cycles

- TPE/TPU (Elastomers): Used in applications requiring flexible sealing or gaskets

- Glass-Filled Plastics: For added strength and dimensional stability

Industries Served:

- Medical Devices & Diagnostics: IV filters, blood filters, drug delivery systems, surgical instruments

- Automotive: Fuel system filters, air and oil filter housings, hydraulic filters

- Water Filtration & Treatment: Portable and residential water filters, membrane supports, flow restrictors

- Food & Beverage: Dairy, brewing, and beverage processing filters made from food-grade plastics

- Consumer Products: Vacuum cleaner filters, appliance filtration systems, small engine applications

- Industrial Equipment: Chemical processing, inkjet filtration, and fluid handling systems

Capabilities:

- Tight-tolerance molding for micron-level filtration components

- Insert molding and overmolding with mesh, screens, or media

- Custom tooling, prototyping, and high-volume production

- ISO-certified quality systems and traceability

- Post-mold assembly and ultrasonic welding available

Contact us today to request a quote or discuss your plastic injection filter application.