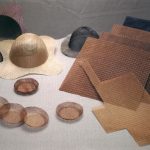

Fiberglass Filters for the Foundry Industry

We specialize in high-performance fiberglass filters engineered for the foundry industry. Available in standard fiberglass, ceramic-coated, and zirconium-coated variants, our filters offer exceptional thermal resistance and superior filtration for non-ferrous metal casting.

Gallery

Filter Types Available

- Plain Fiberglass Filters - Cost-effective filtration for general foundry applications.

- Ceramic-Coated Fiberglass Filters - Enhanced thermal stability, suitable for higher temperature alloys.

- Zirconium-Coated Filters - Ultra-high-temperature resistance and chemical inertness for critical casting ap

Applications by Alloy

| Alloy | Recommended Filter Type | Key Benefits |

|---|---|---|

| Aluminum | Ceramic or Zirconium-Coated | Prevents oxide formation, improves flow quality |

| Brass/Bronze | Zirconium-Coated | Withstands high temp and aggressive melt chemistries |

| Zinc Alloys | Standard Fiberglass | Economical option for low-temp filtering |

| Magnesium | Ceramic-Coated | Thermal durability and low reactivity |

Specification Sheet

| Mesh Size | Weave Type | Temp Resistance | Available Coatings | Typical Use |

|---|---|---|---|---|

| 32 LPI | Plain Weave | Up to 1400F (760C) | Ceramic, Zirconium | Aluminum, brass |

| 36 LPI | Leno Weave | Up to 1650F (900C) | Ceramic, Zirconium | Bronze, high-temp alloys |

| 40 LPI | Basket Weave | Up to 1650F (900C) | Ceramic, Zirconium | Molten copper, zinc |

| 55 PPI | Tight Weave | Up to 1650F (900C) | Ceramic, Zirconium | Precision castings |

Custom shapes, disc formats, and sock filters available upon request.

Why Choose Our Fiberglass Filters?

- High Thermal Endurance

- Optimized Metal Flow and Turbulence Reduction

- Wide Range of Mesh Sizes and Weaves

- Available in Standard, Ceramic-Coated, and Zirconium-Coated Options

- Custom Shapes, Cones, Cups, and Socks Available

Printable Page

Get a Quote

Technical Specifications

The specifications below define filtration performance, porosity ranges, and material options for ScreenTek sintered metal filters, supporting engineering evaluation and system design in demanding service conditions.

| Number | Warp Diameter (mm / in) | Fill Diameter (mm / in) | Strand Count per 10 cm | Holes per cm² | Opening Size (cm² / in²) | Open Area % | Weave Type |

|---|---|---|---|---|---|---|---|

| 30L6 | 1.143 (0.045) | 1.295 (0.051) | 19 x 19 | 4 | 0.1635 (0.0253) | 59.0 | Leno |

| 31L4 | 1.016 (0.040) | 1.067 (0.042) | 23.4 x 25.5 | 6 | 0.0930 (0.0144) | 55.5 | Leno |

| 32L | 0.864 (0.034) | 0.965 (0.038) | 28.2 x 26.8 | 8 | 0.0742 (0.0115) | 56.1 | Leno |

| 33L6 | 1.295 (0.051) | 1.194 (0.047) | 32 x 26.8 | 9 | 0.0464 (0.0071) | 39.8 | Leno |

| 34L | 0.864 (0.034) | 0.940 (0.037) | 34.3 x 29 | 10 | 0.0512 (0.0079) | 50.9 | Leno |

| 34P4 | 0.787 (0.031) | 1.016 (0.040) | 37.3 x 31 | 12 | 0.0418 (0.0065) | 48.4 | Plain |

| 36F | 0.686 (0.027) | 1.118 (0.044) | 40.9 x 34 | 14 | 0.0321 (0.0049) | 44.6 | Plain |

| 36L | 0.914 (0.036) | 0.864 (0.034) | 38.4 x 36 | 14 | 0.0322 (0.0049) | 44.5 | Leno |

| 36P | 0.686 (0.027) | 0.838 (0.033) | 40.9 x 37.8 | 15 | 0.0315 (0.0048) | 48.7 | Plain |

| 36P4 | 0.787 (0.031) | 1.067 (0.042) | 37.3 x 41 | 15 | 0.0260 (0.0040) | 39.7 | Plain |

| 40F | 0.686 (0.027) | 1.118 (0.044) | 40.9 x 37.8 | 15 | 0.0269 (0.0041) | 41.6 | Plain |

| 40L | 0.940 (0.037) | 0.864 (0.034) | 43.8 x 36 | 16 | 0.0255 (0.0040) | 40.3 | Leno |

| 40P | 0.686 (0.027) | 0.838 (0.033) | 44.9 x 44.4 | 20 | 0.0218 (0.0033) | 43.5 | Plain |

| 40P4 | 0.813 (0.032) | 0.991 (0.039) | 36.8 x 34.1 | 13 | 0.0368 (0.0057) | 46.3 | Plain |

| 42F | 0.762 (0.030) | 1.118 (0.044) | 44.9 x 38 | 17 | 0.0222 (0.0034) | 37.8 | Plain |

| 42P | 0.737 (0.029) | 0.864 (0.034) | 44.9 x 46.5 | 21 | 0.0191 (0.0030) | 40.1 | Plain |

| 43FK | 0.762 (0.030) | 1.118 (0.044) | 54 x 42 | 23 | 0.0138 (0.0021) | 31.2 | Plain |

| 43P | 0.737 (0.029) | 0.864 (0.034) | 54 x 50.6 | 27 | 0.0124 (0.0019) | 33.9 | Plain |

| 43P4 | 0.889 (0.035) | 1.168 (0.046) | 54 x 47 | 25 | 0.0092 (0.0014) | 23.4 | Plain |

| 55F | 0.533 (0.021) | 0.787 (0.031) | 65.8 x 56.9 | 37 | 0.0095 (0.0015) | 35.9 | Plain |

| 55P | 0.533 (0.021) | 0.686 (0.027) | 66.4 x 64.9 | 43 | 0.0083 (0.0013) | 35.9 | Plain |

| 59F | 0.559 (0.022) | 0.838 (0.033) | 73.6 x 62.6 | 46 | 0.0061 (0.0009) | 28.5 | Plain |

| 59P | 0.610 (0.024) | 0.737 (0.030) | 74.3 x 72.6 | 54 | 0.0048 (0.0007) | 26.0 | Plain |

| 65F | 0.660 (0.026) | 0.864 (0.034) | 82.1 x 65 | 53 | 0.0038 (0.0006) | 20.1 | Plain |

| 65P | 0.660 (0.026) | 0.762 (0.030) | 81.3 x 77.9 | 63 | 0.0030 (0.0005) | 18.8 | Plain |