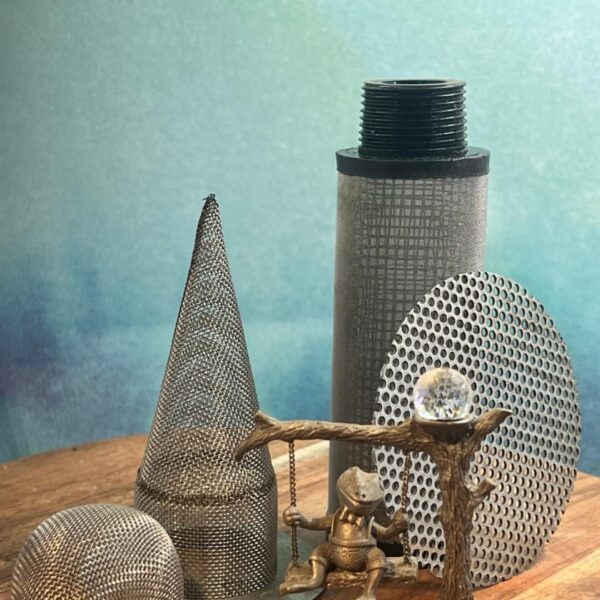

Fabricated Parts

Specialty Custom Filters for Industrial Applications

We specialize in high-performance fiberglass filters engineered for the foundry industry. Available in standard fiberglass, ceramic-coated, and zirconium-coated variants, our filters offer exceptional thermal resistance and superior filtration for non-ferrous metal casting.

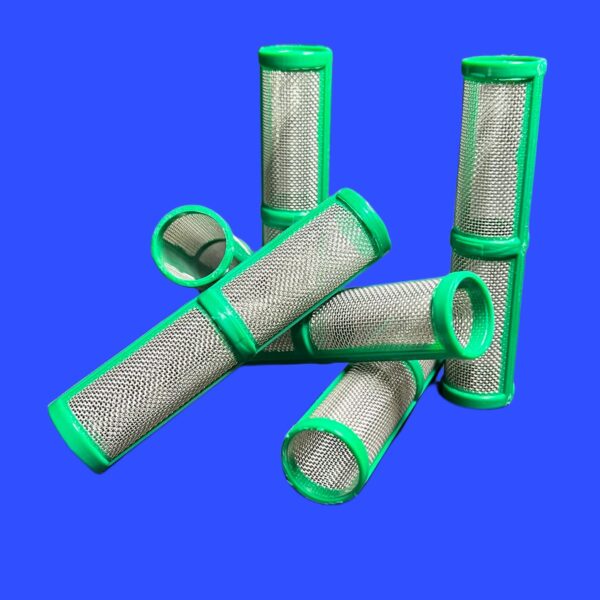

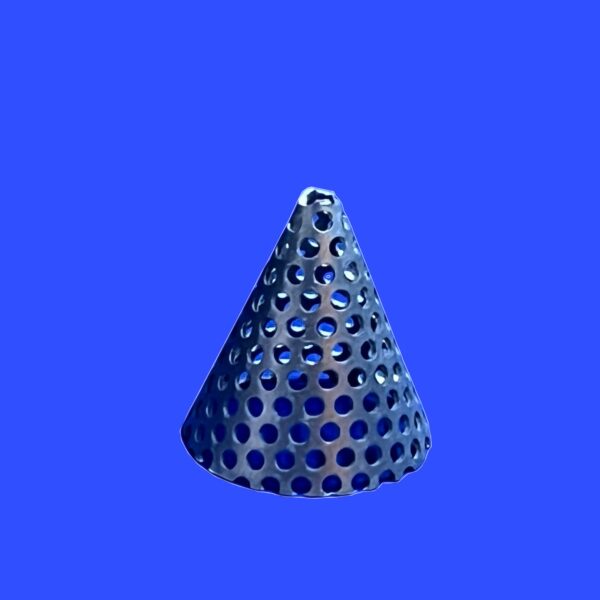

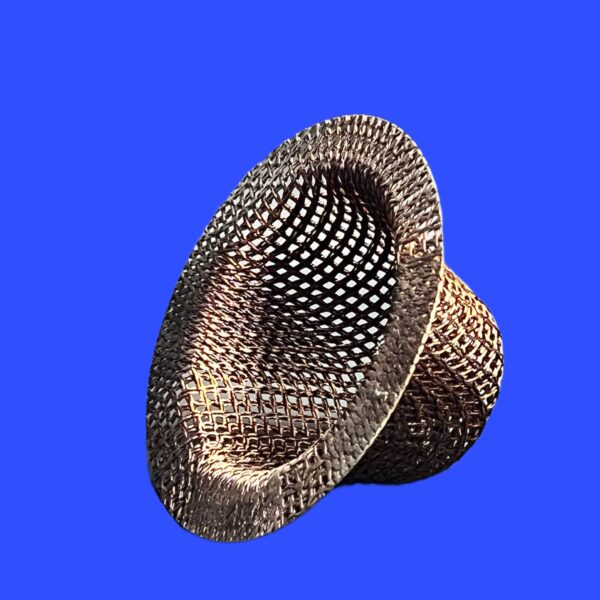

Specialty custom filters are engineered to meet the unique demands of diverse industrial applications, offering precise filtration performance tailored to specific processes. These filters can be fabricated from a wide range of materials, including stainless steel, brass, bronze, aluminum, and specialty alloys, to withstand harsh operating environments such as high temperatures, corrosive chemicals, and high-pressure systems. Industries such as pharmaceuticals, petrochemicals, food processing, water treatment, and automotive manufacturing rely on custom filtration solutions to ensure product quality, equipment protection, and operational efficiency. Designed for exacting tolerances, these filters can be manufactured in various shapes, sizes, and micron ratings to meet stringent engineering specifications.

Among the most common types of specialty filters are plastic injection molded filters, sintered filters, and precision wire mesh assemblies. Plastic injection molded filters offer lightweight, corrosion-resistant solutions ideal for fluid handling, chemical processing, and hydraulic systems. Sintered filters, available in metal or synthetic media, provide high structural strength and excellent particle retention, making them ideal for applications requiring uniform porosity and backwash cleaning. Wire mesh filters offer versatility in filtration, with mesh counts ranging from coarse to ultra-fine for everything from straining large debris to filtering microscopic particles. Together, these specialized filtration technologies provide customized solutions that optimize performance, extend equipment life, and reduce downtime across a wide range of industrial sectors.